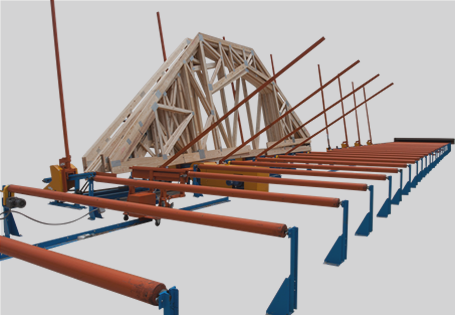

Cyber A/T®

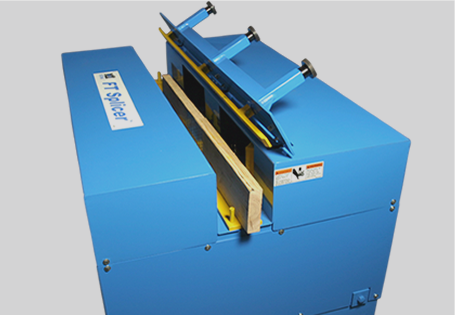

Component Saw

A component saw with up to 6 blades for high-speed batch cutting.

Features

High-speed

batch cutting

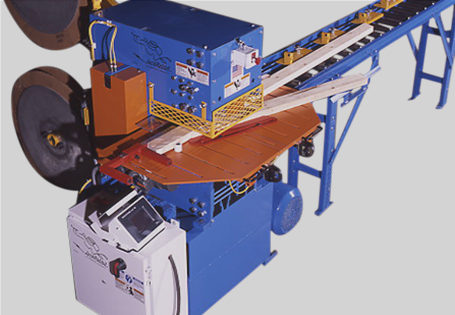

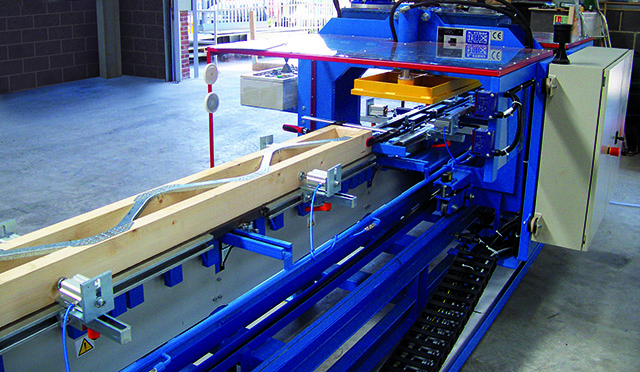

- Automated – A computer-controlled saw with fully powered features.

- Cuts 2×3 and 2×4 lumber.

- 5 or 6 saw blades – Can cut just about anything an architect can think up.

Cyber A/T Saw Overview Video

Specifications

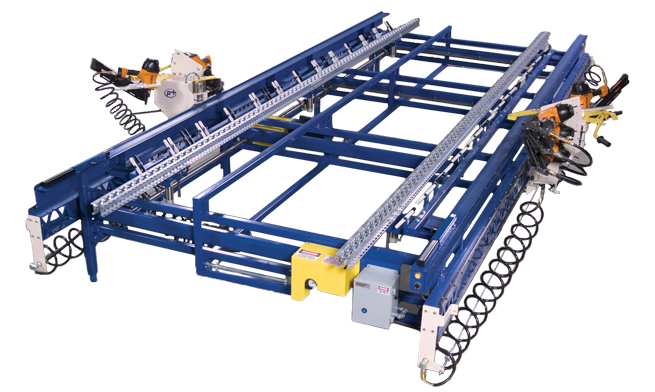

Fast setups, accurate position resolution, fast processing, and rarely needed calibrations! You can have it all with the Cyber®A/T component saw. It’s a computer-controlled saw with fully powered features and options.

- State-of-the-art absolute encoders

- Network ready 10base-T connection

- All blade axes and on-saw conveyor adjustments are powered

- Ability to take blades in and out of cut

- Electronic lumber counter

- Rack and pinion adjustable lumber stop

- Center lumber support for long boards

- Heel cut skid bar to support ends (2nd bar optional)

- Floor truss web riser bars for cutting 4×2 boards

- English and Spanish software on every saw

PHYSICAL DATA

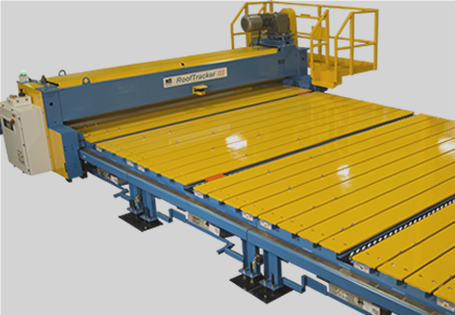

| Dimensions: | 32′ L x 15′ 1″ W x 9′ 1″ H |

| Blades #1 and #4: | 7 hp, 3600 rpm, 20″ blade |

| Blades #2 and #3: | 7 hp, 3600 rpm, 16″ blade |

| Blade #5 and #6 (optional) | 13 hp, 1800 rpm, 32″ blade |

| lnfeed chain: | Heavy-duty #2120 w/flights to push lumber |

| Pneumatic requirements: | 100 psi |

| Approx. weight: | 18,000 lb |

PERFORMANCE DATA

| Modes: | Manual, Semiauto, Automatic |

| Lumber size: | 2×3 up to 2×12 (standard orientation) 4×2 (floor truss orientation) |

| Straight cut length (max): | 20′ |

| Straight cut length (min): | Manual Mode = 15″ Semi and Auto Modes = 16-9/16″ |

| Accuracy: | (+/-) .005″ centerline, .10″ angulation, 1/16″ carriage travel |

| Waste conveyor belt: | 24″ wide, operates automatically |

| HMI: | Touch screen computer, Windows® operating software |

| Brake: | Pneumatic brakes on all saw blades |

ELECTRICAL DATA

| Electrical Specs | 230 VAC, 60 Hz, 3-phase (other voltages require transformer) |

| E-stops | Pushbuttons and pull-cord |

| Safety Compliance | UL (panels), OSHA |

| Indicators of Movement | Horn |

| Labels | Bilingual or ISO |

- Sixth saw blade

- Incline waste conveyor mounted at either end

- Catcher Display

- Inker

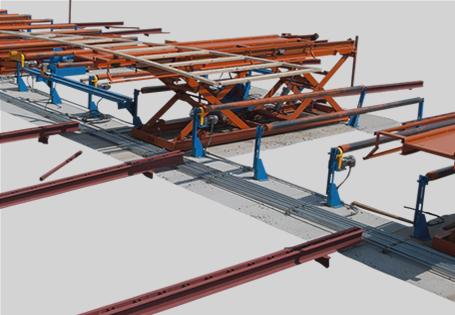

- Ready-Feed Lumber Conveyor on infeed

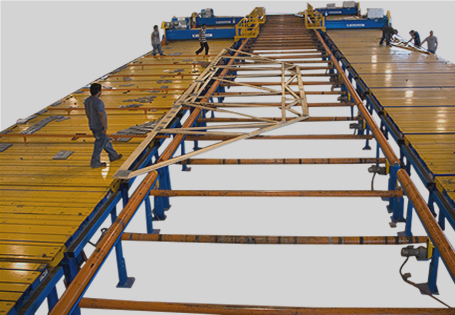

- Various material handling options for outfeed

- Spanish equipment manual

DOWNLOAD THE FULL SPEC SHEET

Download PDFMACHINERY SUPPORT & RESOURCES

MiTek offers consulting, testing, documentation, design assistance and prompt customer service. Visit our Support, Training and Knowledge Base center for more information.

MACHINERY EQUIPMENT

View more of the most complete, reliable, and productive component manufacturing equipment in the industry.